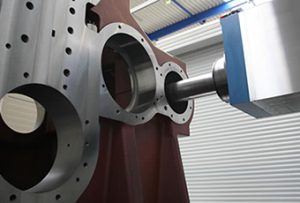

WZ series horizontal CNC drilling and milling machine

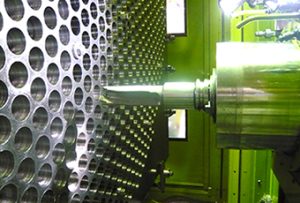

This machine tool is a horizontal CNC drilling and milling machine widely used in industries such as petroleum, chemical, papermaking machinery, heat exchangers, etc. It is particularly suitable for drilling and chamfering holes on flange end faces of long shafts, as well as for rigid tapping and light milling of holes.

Milling

Drilling

Tapping

★This machine tool is a horizontal CNC drilling and milling machine widely used in industries such as petroleum, chemical, papermaking machinery, heat exchangers, etc. It is particularly suitable for drilling and chamfering holes on flange end faces of long shafts, as well as for rigid tapping and light milling of holes.

★The bed adopts welded parts of steel plate or casting structure, and has undergone artificial thermal aging treatment, ensuring stable accuracy. There are multiple sets of adjustable pad irons on the bottom, which can easily adjust the level of the bed.

★The column adopts welded parts of steel plate or casting structure, with internal counterweights that balance the weight of the vertical sliding platform through two plate chains.

★The ram type power box is hung on the column through a vertical sliding plate, and is driven by a servo motor through a synchronous belt deceleration and a ball screw pair to achieve horizontal (Z-direction) feed of the power head.

★Spindle taper hole BT50, with butterfly spring automatic tool pulling mechanism, hydraulic cylinder loosening tool, it is very convenient to replace the tool. It can clamp hard alloy internal cold drill bit and high speed steel twist drill bit, and has spindle taper hole blowing cleaning function.

★The worktable has T-slots, and the V-shaped locating fixture is fixed on the table, together with a pressure plate to secure the workpiece on the worktable.

| Model | WZ20 | WZ30 | Unit |

| Workpiece diameter(One time clamping) | Φ500—Φ2000 | Φ500—Φ3000 | mm |

| Maximum workpiece thickness | 400 | 500 | mm |

| Spindle taper hole | BT50 | BT50 | |

| Maximum drilling diameter | Φ80 | Φ80 | mm |

| Maximum tapping diameter | M30 | M42 | mm |

| Spindle speed | 30—3000 | 30—3000 | r/min |

| Spindle motor power | 22 | 37 | kW |

| Electrical system | Siemens 828Dsl/840Dsl | ||