JXZ Series Gantry Moving Boiler Header Tube High Speed CNC Drilling And Milling Machine

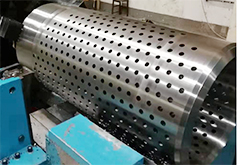

The gantry moving boiler header tube high speed CNC drilling and milling machine is used for drilling and welding groove processing of boiler header tubes in the boiler industry.

Drilling

Welding Bevel Milling

Boiler header tube-Boiler Industry

★The machine adopts the BT50 precision rigid spindle, which is powered by a high-power spindle motor through a synchronous belt wheel, and can achieve high-speed drilling and welding groove milling.

★The machine adopts our unique structure of dual gantry and dual workstations. Short tube can process two pieces at the same time, and long tube can process one piece with dual gantries at the same time.

★The boiler header tube support frame adopts two types: lifting support frame and fixed support frame. When rotating, lifting the support frame will lift the workpiece and then lower it onto the fixed support frame during processing to prevent slipping.

★CNC indexing head: installed at both ends of the bed, and can be moved along the X-axis. A self-centering chuck is installed on it for easy installation of workpieces.

| JXZ Series Gantry Moving Boiler Header Tube High Speed CNC Drilling And Milling Machine | Unit | ||

| Processing boiler header tube size range | Outer diameter range | Φ75—Φ1100 | mm |

| Maximum length | 12/Dual station

26/Single station |

m | |

| CNC indexing head (A-axis) | Indexing rotation speed (CNC) | 0—5 | r/min |

| Indexing servo motor power | 7/10 | Kw | |

| Drilling head and vertical slide

(Z axis) |

Spindle taper hole | BT50 | |

| Maximum drilling diameter | Φ80 | mm | |

| Maximum core drilling diameter | Φ200 | mm | |

| Spindle speed (servo) | 30—3000 | r/min | |

| Max. spindle torque | 700 | Nm | |

| Spindle motor power | 37 | kW | |

| Electrical system | Siemens 828Dsl/840Dsl | ||